|

Image: SAMUEL VELASCO

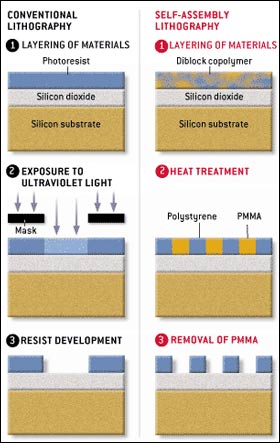

OLD AND NEW: Conventional

lithography exposes a photoresist to ultraviolet light. An

etchant then removes the exposed part of the photoresist.

Self-assembly patterning occurs when a diblock copolymer is

heated, thereby separating the two polymers in the material

into defined areas before the PMMA is etched away. The

template of cyclindrical holes is transferred into the silicon

dioxide before the holes are filled with nanocrystalline

silicon used to store data (steps not

shown). | Self-assembly has become a

critical implement in the toolbox of nanotechnologists. Scientists

and engineers who explore the nano realm posit that the same types

of forces that construct a snowflake--the natural attractions and

repulsions that prompt molecules to form intricate patterns--can

build useful structures--say, medical implants or components in

electronic chips. So far much of the work related to self-assembling

nanostructures has been nothing more than demonstrations in

university laboratories. To go beyond being a scientific curiosity,

these nanotech materials and techniques will have to get from

benchtop to a $2-billion semiconductor fabrication facility.

Four years ago two members of the technical staff at the IBM

Thomas J. Watson Research Center in Yorktown Heights, N.Y., began to

contemplate how they might transform the vision of self-assembly

into a practical reality. The collaborators, Charles Black and

Kathryn Guarini, knew that the grand academic ambitions of making an

entire set of chip circuits from self-assembly had to be set aside.

Instead the best way to begin, they thought, might be to replace a

single manufacturing step. "The idea was that if we could ease the

burden in any of the hundreds of steps to make a chip, we should

take advantage of that," Black says.

They first had to

select what type of molecules might self-construct without

disrupting routine silicon manufacturing practices. Polymers were an

obvious choice. They make up the "resist" used in

photolithography--the material that, once exposed to ultraviolet or

shorter-wavelength light, is washed away to form a circuit pattern.

During the first two years of their quest, the duo spent time

learning about polymers and the optimal temperatures and thicknesses

at which they would self-assemble. They built on the work of Craig

J. Hawker of the IBM Almaden Research Center in San Jose, Calif.,

and that of former IBMer Thomas P. Russell, a polymer scientist at

the University of Massachusetts at Amherst. Both had done research

on how polymers self-assemble on silicon. With this knowledge, Black

and Guarini even started making things. |

Image: SAMUEL VELASCO

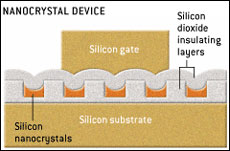

FLASH MEMORY: A layer of

self-assembled silicon nanocrystals is inserted into an

otherwise standard device as part of a novel IBM manufacturing

process. | The two researchers appeared

at conferences, giving presentations about honeycomb patterns that

had self-assembled. But that accomplishment consisted of little more

than PowerPoints, the type of through-the-microscope images found in

abundance at any academic conference on nanotechnology. What would

the nano patterns be good for? How could they be integrated into a

fabrication line? Could they best circuit-patterning techniques that

had already received hundreds of millions of dollars of investment?

Finally, last year, the pair demonstrated how a self-assembled

honeycomb pattern might work in a real manufacturing facility. The

material chosen for the demo was a diblock copolymer, one in which

two polymers--in this case, polystyrene (Styrofoam) and

polymethylmethacrylate (Plexiglas, or PMMA)--are tied together by

chemical bonds. When spun onto the surface of a rotating silicon

wafer, the two polymers separate, as if they were oil and water.

Although the molecules stretch out, the chemical bonds keep them

attached. Subsequent heat treatment exacerbates this elongation. In

the end, PMMA ends up concentrated in small cylinders surrounded on

all sides by the polystyrene. The diblock copolymer thus forms on

its own into a nearly complete honeycomblike template.

To finish creating the 20-nanometer-wide pores, an organic etching

solvent removes the PMMA. A subsequent etching step transfers

the same honeycomb pattern into an underlying layer of more

robust silicon dioxide. Then a coating of amorphous silicon

gets deposited across the surface of the wafer. A gas etches

away the silicon except for that deposited in the holes. All

that is left are nanocrystalline cylinders surrounded by silicon

dioxide. The final steps place an insulating layer and a block

of silicon atop the structure, the block forming a "gate" that

turns the electronic device off and on. Black and Guarini's

honeycomb results in a nanostructure that is part of a working

flash-memory device, the kind that retains digital bits even

when a camera or a voice recorder is turned off. The nanocrystalline

cylinders form capacitors where data are stored.

Manufacturing engineers are leery of introducing new technologies

unless a researcher can make a very good case for their adoption.

Self-assembly potentially fits the bill. Creating closely spaced

holes for a flash memory would prove exceedingly difficult with

ordinary lithographic and deposition methods. Forming nanocrystals

using conventional techniques creates elements of different

sizes that are all jumbled together. In contrast, the self-assembled

nanocrystals are evenly spaced and of uniform size, improving

their durability and their capacity to retain a charge while

allowing the cylinders to shrink to smaller than 20 nanometers.

The IBM demonstration served as proof of principle in the strictest

sense of the expression. The company has not made commercial

flash memories for years, so the invention could not be applied

immediately to improve its own manufacturing operations. But

the nanocrystals enabled the pair of researchers to flaunt this

type of nano patterning. "Politically in the company maybe

it wasn't the smartest demonstration we could have done, but

everybody was supportive and could see the power of the technology,"

Black says.

The understanding gained of how to integrate nanomanufacturing

with conventional chipmaking may provide new approaches to fabricating

other IBM electronic components. Making holes and filling them

could create "decoupling" capacitors recessed into

the chip substrate that smooth out fluctuations in the power

supplied to a chip.

Using a variant of nano patterning, a self-assembling polymer

could also create tiny, finger-shaped silicon protrusions sticking

up from the underlying substrate. These fingers would constitute

the "channel" in a transistor through which electrons

flow--but one in which electrons flow vertically instead of

across a chip, as in today's devices. The gate to turn the transistor

off and on could encircle the silicon finger. The geometry might

prevent electrons from "tunneling," or leaking, through

the channel when the transistor is in the off state, a constant

threat when feature sizes become very small.

Ultimately, self-assembly might play a much bigger role in fashioning

electronic circuits. But the incrementalist approach of Black

and Guarini may represent the most promising way to get nanotechnology

adopted as a real manufacturing tool. "The greatest excitement

is that these materials aren't just in the polymer-science laboratory

anymore," Black says. A small step for small manufacturing.

|